Active construction sites operate under constant pressure. Multiple trades work in parallel, schedules shift daily, and access requirements change as structures rise. In these environments, vertical access equipment must support safe movement without slowing progress or creating new hazards. When lifting equipment is misused, even small oversights can lead to injuries, shutdowns, or inspection failures.

These risks are especially common when relying on rented personnel lifts. Temporary access solutions demand the same level of planning and control as permanent systems. Proper selection and operation of a single man lift, or other personnel lift are essential to maintaining safety and productivity.

Understanding Personnel Lifts in Active Construction Environments

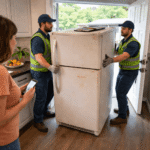

Personnel lifts for rent are designed to move workers vertically for installation, inspection, and finishing tasks. These systems differ in height, capacity, and stability. A single man lift, or one man lift rental, is typically used for focused tasks, while larger platforms support extended access. Understanding site conditions is critical before deployment.

Mistake #1: Choosing the Wrong Type of Personnel Lift for the Job

Selecting equipment based solely on availability often leads to a mismatch. A single man lift may lack reach or stability for certain tasks. Choosing the correct personnel lifts for rent ensures the equipment aligns with the required height, load, and access.

Mistake #2: Ignoring Load Capacity and Occupancy Limits

Overloading is a common safety violation. Exceeding rated limits on a one man lift rental increases mechanical stress and tipping risk. Load limits must account for tools, materials, and operator weight on all personnel lifts for rent.

Mistake #3: Skipping Pre-Use Inspections

Rental equipment still requires daily inspection. Controls, guardrails, brakes, and emergency systems must be checked before use. Failing to inspect personnel lifts for rent increases the likelihood of mechanical failure during operation.

Mistake #4: Assuming Rental Equipment Is Always Site-Ready

Delivery does not guarantee readiness. Setup conditions, surface stability, and clearance must be verified. Even a properly maintained single man lift can become unsafe if deployed incorrectly on site.

Mistake #5: Operating Personnel Lifts Without Proper Training

Untrained operators create significant risk. Each one man lift rental has unique controls and response behavior. Proper training ensures personnel lifts for rent are used within their intended operating limits.

Mistake #6: Using Personnel Lifts on Inadequate or Unstable Ground

Ground conditions directly affect stability. Soft soil, debris, or uneven surfaces compromise lift balance. Personnel lifts for rent must be positioned on stable, load-bearing surfaces to prevent tipping.

Mistake #7: Poor Coordination With Other Trades and Site Traffic

Congested sites increase collision risk. Lift paths must be coordinated with other trades, equipment movement, and material flow. Clear access planning improves the safe use of single-man lift systems.

Mistake #8: Ignoring Environmental and Weather Conditions

Wind, rain, and temperature changes affect lift performance. Lightweight one man lift rental units are particularly sensitive to environmental forces. Operating limits must be respected for all personnel lifts for rent.

Mistake #9: Failing to Plan for Emergency Situations

Emergency descent and rescue procedures are often overlooked. Operators must understand how to respond to power loss or system faults. Emergency planning is essential for the safe operation of personnel lifts for rent.

Mistake #10: Extending Short-Term Rentals Without Re-Evaluating Site Needs

Short-term solutions often evolve into long-term use. Continuing a one-man lift rental without reassessing height, traffic, and load requirements increases risk. Equipment suitability should be reviewed as site conditions change.

Common Safety and Compliance Gaps Inspectors Identify

Inspectors frequently identify issues such as missing documentation, inadequate training records, and improper use. These gaps are common across personnel lifts for rent when oversight is inconsistent.

How Avoiding These Mistakes Improves Site Safety and Productivity

Avoiding these errors reduces downtime, prevents incidents, and improves workflow efficiency. Proper use of single man lift systems supports predictable access and safer task execution.

Best Practices for Using Personnel Lifts for Rent on Active Sites

Best practices include regular inspections, clear access planning, documented training, and continuous reassessment. Following these steps ensures personnel lifts for rent remain aligned with site conditions.

When to Reassess or Upgrade Your Personnel Lift Rental

As structures rise and tasks evolve, access needs change. Reassessment ensures the selected one man lift rental or alternative system continues to meet operational demands safely.

Preventing Mistakes Before They Lead to Incidents or Delays

Mistakes involving temporary access equipment often have lasting consequences. Careful planning, training, and oversight reduce risk and support consistent site performance. When vertical access becomes more complex, a properly specified personnel elevator may offer a safer and more efficient solution.

UCEL Inc. provides engineered access and lifting solutions designed for active construction environments across Canada and the USA. Connect with UCEL Inc. to select personnel lift systems that prioritize safety, compliance, and uninterrupted site progress.