Facility managers evaluating conveyor systems often face a fundamental decision between simplicity and automation. The choice between gravity-driven equipment and motorized systems influences throughput, labor requirements, layout flexibility, and long-term operating costs. This decision becomes even more relevant as operations scale and workflows evolve, especially in environments where spantech conveyors and modular automation solutions are frequently considered for efficiency gains.

Both gravity roller and powered conveyors play essential roles in modern material flow. Each system offers distinct advantages depending on product type, volume, and control requirements. Understanding how these systems differ helps align conveyor selection with real operational needs rather than surface-level cost comparisons.

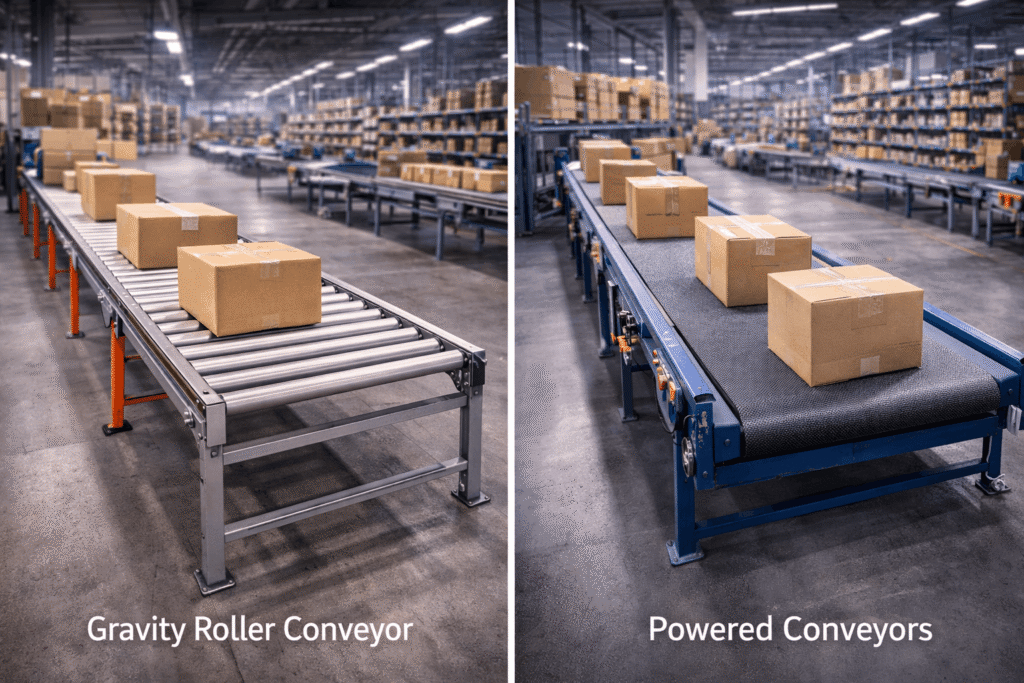

What Is a Gravity Roller Conveyor?

A gravity roller conveyor moves products using gravity rather than motors. Rollers are installed on a slight decline, allowing cartons, totes, or pallets to travel forward without powered assistance. These systems rely on product weight and consistent flow to function effectively.

Gravity roller conveyors are valued for their mechanical simplicity, low upfront cost, and minimal energy use. They are commonly installed in areas where controlled speed and precise positioning are not critical.

What Are Powered Conveyors?

Powered conveyors use motors to move products along a defined path. These systems include belt conveyors, roller conveyors with powered rollers, and more advanced configurations, such as accumulation conveyors designed to manage product spacing and buffering.

Powered systems deliver consistent motion regardless of load weight or incline, making them suitable for automated environments and high-throughput operations.

Key Design Differences Between Gravity and Powered Conveyors

The most obvious difference lies in the drive mechanisms. Gravity systems contain no motors, gearboxes, or controls. Powered conveyors integrate electrical components, drives, sensors, and control logic.

Structural design also varies. Gravity conveyors often feature simpler frames, while powered systems are engineered to support motors, wiring, and protective guarding.

Load Handling and Throughput Capabilities

Gravity roller conveyors perform best with uniform, free-moving loads. Variations in weight or packaging can disrupt flow and cause stoppages.

Powered conveyors handle a wider range of products and maintain consistent throughput. Load capacity and speed are controlled mechanically rather than relying on gravity alone.

Control, Accumulation, and Product Protection

Gravity systems offer limited control over product spacing and speed. Collisions and product contact are more difficult to manage without manual intervention.

Powered conveyors support controlled accumulation, indexing, and gentle product handling. An accumulation conveyor allows products to queue without contact, reducing damage and improving downstream efficiency.

Layout Flexibility and Facility Requirements

Gravity conveyors require elevation changes to maintain movement, which can limit layout options in flat facilities.

Powered systems operate on level floors and can navigate curves, merges, and elevation changes using additional components, offering greater layout flexibility.

Labor, Ergonomics, and Safety Considerations

Gravity systems often require manual assistance to start or stop product movement, increasing physical strain on workers.

Powered conveyors reduce manual handling and improve ergonomic conditions. Integrated safety controls further reduce workplace risk.

Energy Use and Operating Costs

Gravity roller conveyors consume no electricity, resulting in minimal operating costs.

Powered conveyors incur energy costs but often offset them through labor savings, higher throughput, and reduced product damage.

Maintenance and Reliability Comparison

Gravity systems require basic maintenance, such as roller replacement and frame alignment.

Powered conveyors involve motors, sensors, and controls that require scheduled inspection. However, predictable maintenance supports consistent reliability.

Upfront Cost vs Long-Term ROI

Gravity conveyors typically cost less initially but may limit scalability.

Powered systems require higher upfront investment but often deliver stronger long-term returns through automation and efficiency gains.

Common Applications for Gravity Roller Conveyors

Typical uses include shipping lanes, picking zones, and simple carton transport where speed control is not critical.

Common Applications for Powered Conveyors

Powered conveyors are used in packaging lines, distribution centers, manufacturing cells, and automated sorting systems.

When a Hybrid Conveyor System Makes Sense

Many facilities combine gravity and powered sections to balance cost and performance. Hybrid layouts optimize flow while controlling capital expense.

How to Choose Between Gravity Roller and Powered Conveyors

Selection depends on product characteristics, throughput goals, labor strategy, and future growth plans. Evaluating these factors together leads to better system alignment.

Selecting the Conveyor That Fits Your Workflow

Gravity and powered conveyors serve different roles within material movement strategies. The right choice depends on control needs, scalability, and operational efficiency. Conovey delivers engineered conveyor solutions that align with facility goals and production demands.

Connect with Conovey to design a material handling conveyor system that supports reliable flow, smart automation, and long-term performance.