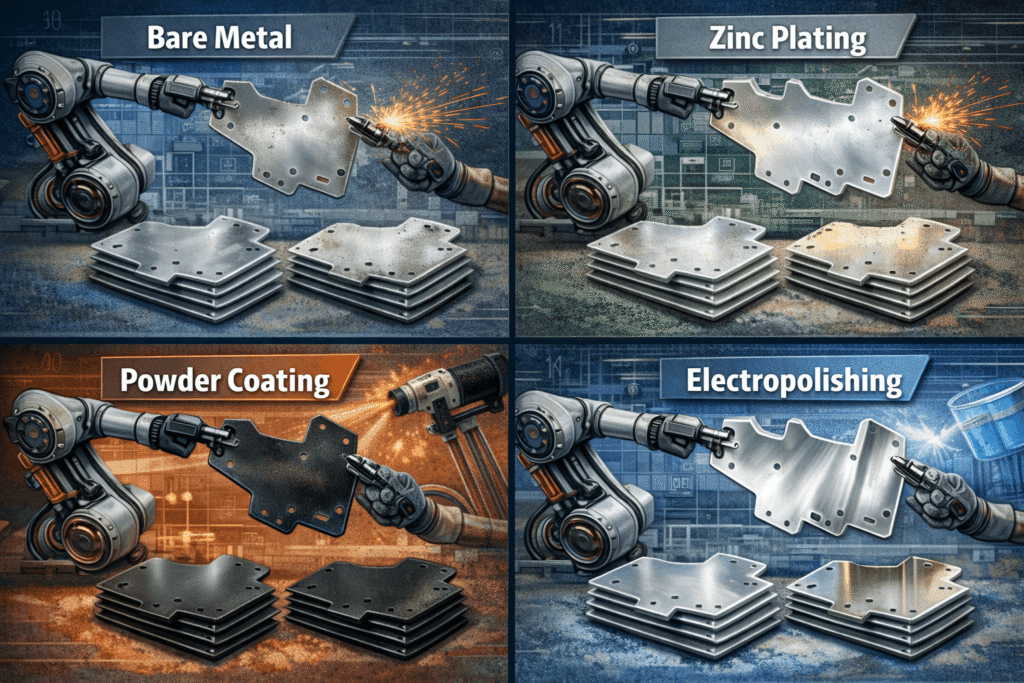

Metal stampings are defined not only by how accurately they are formed, but by how they are finished. While stamping creates the shape and structure of a component, finishing determines how that part performs over time. Corrosion resistance, surface durability, dimensional stability, and even assembly reliability are all influenced by the selected finishing process.

For manufacturers across Canada that rely on custom metal stamping, choosing the right finishing option is a functional decision, not an aesthetic one. Each finishing method delivers distinct benefits and limitations depending on material type, operating environment, and end-use requirements. Comparing these options helps ensure stamped components meet performance expectations throughout their service life.

Why Finishing Options Must Be Evaluated Comparatively

Finishing processes are often selected based solely on familiarity or cost. However, each option affects quality in different ways. When evaluated side by side, key differences emerge in how finishes:

- Protect against corrosion and environmental exposure

- Support electrical or mechanical performance

- Influence wear resistance and part longevity

- Affect dimensional consistency and handling safety

Understanding these trade-offs helps manufacturers align finishing choices with application-specific demands rather than relying on one-size-fits-all solutions.

Plating vs Other Finishes: Corrosion Protection and Conductivity

Plating

Plating involves applying a thin metallic layer—commonly zinc, nickel, or tin—onto the stamped part.

Quality impact:

- Strong protection against oxidation and rust

- Improved solderability for electrical components

- Increased surface hardness

Best suited for:

Electronics, medical devices, and applications that are exposed to moisture or corrosive conditions.

Limitations:

- Added processing steps

- Material compatibility must be carefully managed

Compared to coatings or passivation, plating offers superior conductivity but may be more complex.

Powder Coating vs Plating: Durability and Surface Uniformity

Powder Coating

Powder coating creates a thick, uniform protective layer that cures to a hard finish.

Quality impact:

- High resistance to chipping, scratching, and abrasion

- Consistent coverage on complex geometries

- Strong visual uniformity

Best suited for:

Industrial housings, brackets, and commercial components where durability and appearance matter equally.

Limitations:

- Not suitable where electrical conductivity is required

- A thicker coating can affect tight tolerances

When compared to plating, powder coating offers greater mechanical durability but less functional versatility for conductive applications.

Passivation vs Coatings: Stainless Steel Stability

Passivation

Passivation chemically removes surface contaminants from stainless steel without adding a coating.

Quality impact:

- Enhances corrosion resistance by restoring the natural oxide layer

- Maintains a clean, matte surface finish

- Preserves dimensional accuracy

Best suited for:

Food processing, medical, and hygienic environments.

Limitations:

- Limited to stainless steel

- Provides no mechanical wear protection

Unlike coatings or plating, passivation improves material integrity without altering surface thickness.

Deburring Compared to Surface Treatments: Precision and Safety

Deburring

Deburring removes sharp edges and burrs formed during stamping.

Quality impact:

- Improves dimensional accuracy

- Reduces friction during assembly

- Enhances operator safety

Best suited for:

All stamped components that require tight tolerances or manual handling.

Limitations:

- Does not provide corrosion or wear protection

While deburring does not replace surface treatments, it complements all finishing options by improving functional consistency.

How Finishing Choices Compare Across Key Criteria

| Quality Factor | Plating | Powder Coating | Passivation | Deburring |

| Corrosion Resistance | High | High | Moderate–High | None |

| Electrical Conductivity | High | Low | Neutral | Neutral |

| Wear Resistance | Moderate | High | Low | Neutral |

| Dimensional Impact | Minimal | Moderate | Minimal | Improves accuracy |

| Safety & Handling | Moderate | Moderate | Moderate | High |

This comparison highlights why finishing decisions must align with performance priorities rather than cost alone.

Finish Selection and Long-Term Reliability

Even precisely stamped components can fail prematurely if the finishing process does not match the operating environment. Inadequate corrosion protection, excess coating thickness, or unresolved burrs can lead to assembly issues, accelerated wear, or non-compliance with quality standards.

By contrast, a well-matched finishing process supports:

- Longer component service life

- Stable tolerances during operation

- Reduced rework and scrap rates

- More predictable assembly performance

Finishing also plays an increasingly important role in sustainability efforts by minimizing waste and extending the usable life of parts.

Finishing as a Defining Factor in Metal Stamping Quality

No single finishing method is universally superior. Each offers specific advantages that influence quality in different ways. Comparing plating, powder coating, passivation, and deburring side by side makes it clear that finishing is not a final touch—it is a defining stage in the manufacturing process.

By treating finishing as an integrated quality decision, manufacturers can ensure that custom metal stampings meet performance, durability, and reliability expectations.